Sept 22, 2021 Table Read

The full paper can be found here: https://www.sciencedirect.com/science/article/abs/pii/S0925753513001598?via%3Dihub

Two case studies in consumer risk perception and exposure assessment, focusing on mothballs and elemental mercury.

For this Table Read, we will only be reviewing the two case studies presented in the paper.

4. Two case studies: mothballs and mercury

Two case studies illustrate the importance of careful adaptation to context[a][b][c]. In the first case, an expert model of consumer-product use of paradichlorobenzene mothballs is enhanced with information from lay users’ mental models, so the model can become more behaviorally realistic (Riley et al., 2006a). In the second case, the mental models elicitation is enhanced with ethnographic methods including participant observation in order to gain critical information about cultural context of mercury use in Latino and Caribbean communities in the New York area (Newby et al., 2006; Riley et al., 2001a, 2001b, 2006b).

Both cases are drawn from chemical consumer products applied in residential uses. The chemicals considered here – paradichlorobenzene and mercury – have a wide variety of consumer and occupational uses that underscore the importance of considering context in order to attain a realistic sense of beliefs about the chemical, exposure behaviors, and resultant risk.

This analysis focuses on what these case studies can tell us about the process of risk communication design[d] in order to take account of the multidimensional aspects of risk perception as well as the overall cultural context of risk. Thus, risk communications may be tailored to the beliefs held by individuals in a specific setting, as well as to the specifics of their situation (factors physical, social, and cultural) which influence perceptions of and decision making about risk.

4.1. Mothballs

Mothballs are used in homes to control moth infestations in clothing or other textiles. Mothballs are solids (paradichlorobenzene or naphthalene) that sublimate (move from a solid state to a gaseous state) at room temperature. Many are in the shape of balls about 1 in. in diameter, but they are also available as larger cakes or as flakes. The products with the highest exposed surface area (flakes) volatilize more quickly. The product works by the vapor killing adult moths, breaking the insect life cycle.

The primary exposure pathway is inhalation of product vapors, but dermal contact and ingestion may also occur. Cases of ingestion have included children mistaking mothballs for candy and individuals with psychological disorders who compulsively eat household items (Avila et al., 2006; Bates, 2002). Acute exposure to paradichlorobenzene can cause skin, eye, or nasal tissue irritation; acute exposure to naphthalene can cause hemolytic anemia, as well as neurological effects. Chronic exposures to either compound causes liver damage and central nervous system effects. Additional long-term effects of naphthalene exposure include retinal damage and cataracts (USEPA, 2000). Both paradichlorobenzene and naphthalene are classified as possible human carcinogens (IARC Group II B) (IARC, 1999). Since this classification in 1987, however, a mechanism for cancer development has been identified for both naphthalene and paradichlorobenzene, in which the chemicals block enzymes that are key to the process of apoptosis, the natural die-off of cells. Without apoptosis, tumors may form as cell growth continues unchecked (Kokel et al., 2006).

Indoor air quality researchers have studied mothballs through modeling and experiment (e.g., Chang and Krebs, 1992; Sparks et al., 1991, 1996; Tichenor et al., 1991; Wallace, 1991). Research on this topic has focused on developing and validating models of fate and transport of paradichlorobenzene or naphthalene in indoor air. Unfortunately, the effects of consumer behavior on exposure were not considered[i][j]. Due to the importance of the influence of consumer behavior on exposure, it is worth revisiting this work to incorporate realistic approximations of consumer behavior.

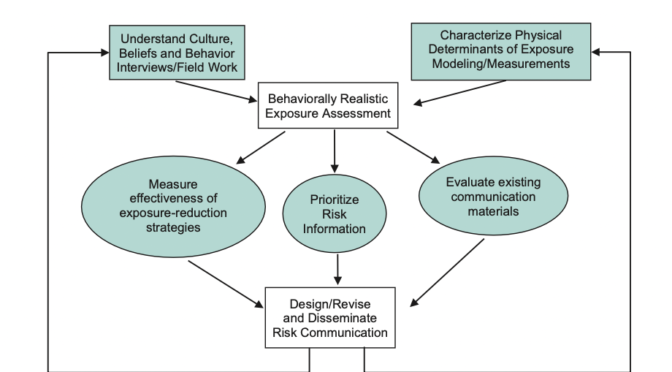

Understanding consumer decisions about purchasing, storage, and use is critical for arriving at realistic exposure estimates as well as effective risk management strategies and warnings content. Consumer decision-making is further based upon existing knowledge and understanding of exposure pathways, mental models of how risk arises (Morgan et al., 2001), and beliefs about the effectiveness of various risk-mitigation strategies. Riley et al. (2001a, 2001b) previously proposed a model of behaviorally realistic exposure assessment for chemical consumer products, in which exposure endpoints are modeled in order to estimate the relative effectiveness of different risk mitigation strategies, and by extension, to evaluate warnings (refer to Fig. 1). The goal is to develop warnings that provide readers with the information they need to manage the risks associated with a given product, including how hazards may arise, potential effects, and risk-mitigation strategies.

4.1.1. Methods

The idea behind behaviorally realistic exposure assessment is to consider both the behavioral and physical determinants of exposure in an integrated way (Riley et al., 2000). Thus, user interviews and/or observational studies are combined with modeling and/or experimental studies to quantitatively assess the relative importance of different risk mitigation strategies and to prioritize content for the design of warnings, based on what users already know about a product. Open-ended interviews elicit people’s beliefs about the product, how it works, how hazards arise, and how they may be prevented or mitigated. User-supplied information is used as input to the modeling or experimental design in order to reflect how people really interact with a given product. Modeling can be used to estimate user exposure or to understand the range of possible exposures that can result from different combinations of warning designs and reading strategies.

Riley et al. (2006a) recruited 22 adult volunteers [k][l][m][n][o][p][q][r]who had used mothballs from the business district in Northampton, Massachusetts. Interview questions probed five areas: motivation for product use and selection; detailed use data (location, time activity patterns, amount and frequency of use); mental models of how the product works and how hazards may arise; and risk perceptions; risk mitigation strategies. Responses were analyzed using categorical coding (Weisberg et al., 1996). A consumer exposure model utilized user-supplied data to determine the concentration of paradichlorobenzene in a two-box model (a room or compartment in which moth products are used, and a larger living space).

4.1.2. Uses

Table 1 illustrates the diversity of behavior surrounding the use[s][t][u][v][w] of mothballs in the home. It is clear that many users behave differently around the product from what one might assume from reading directions or warnings on the package label.

65% of participants reported using mothballs to kill or repel moths, which is its intended use. 35% reported other uses for the product, including as an air freshener and to repel rodents outdoors. Such uses imply different use behaviors related to the amount of product used and the location where it is applied. Effective use of paradichlorobenzene as an indoor insecticide requires use in an enclosed space, the more airtight the better. Ventilation is not recommended, and individuals should limit their exposure to the non-ventilated space. In contrast, use as a deodorizer disperses paradichlorobenzene throughout a space by design.

These different behaviors imply different resultant exposure levels. For use as an air freshener, the exposure might be higher due to using the product in the open in one’s living space. Exposures might also be lower, as in the reported outdoor use for controlling mammal pests.

A use not reported in this study, perhaps due to the small sample size, or perhaps due to the stigma associated with drug use, is the practice of huffing or sniffing – intentional inhalation in order to take advantage of the physiological effects of volatile chemicals (Weintraub et al., 2000). This use is worth mentioning due to its high potential for injury, even if this use is far less likely than other uses reported here.

The majority of users place mothballs outside of sealed containers in order to control moths, another use that is not recommended by experts or on package labeling[x][y][z][aa][ab][ac][ad][ae]. Even though the product is recommended for active infestations, many users report using the product preventively, increasing the frequency of use and resultant exposure above recommended or expected levels. Finally, the amount used is greater than indicated for a majority of the treatment scenarios reported. These variances from recommended use scenarios underscore the need for effective risk communication, and suggest priority areas for reducing risk.

These results indicate a wide range of residential uses with a variety of exposure patterns. In occupational settings, one might anticipate a similarly broad range of uses. In addition to industrial and commercial uses as mothballs (e.g., textile storage, dry cleaning) and air fresheners (e.g., taxi cabs, restaurants), paradichlorobenzene is used as an insecticide (ants, fruit borers) or fungicide (mold and mildew), as a reagent for manufacturing other chemical products, plastics and pharmaceuticals, and in dyeing (GRR Exports, 2006).

4.1.3. Exposures

Modeling of home uses illustrates the range of possible exposures[af] based on self-reported behavior, and compares a high and low case scenario from the self-reports to an ‘‘intended use’’ scenario that follows label instructions exactly.

Table 2 shows the inputs used for modeling and resultant exposures. The label employed for the expected use scenario advised that one box (10 oz, 65 mothballs) should be used for every 50 cubic feet (1.4 cubic meters) of tightly enclosed space. Thus, for a 2-cubic-meter closet, 90 mothballs were assumed for the intended use scenario. The low exposure scenario involved a participant self-report in which 10 mothballs were placed in a closed dresser drawer, and the high exposure scenario involved two boxes of mothballs reportedly placed in the corners of a 30-cubic-meter bedroom.

Results show that placing moth products in a tightly enclosed space significantly reduces the concentration in users’ living space.[ag][ah][ai][aj][ak][al][am][an] The high level of exposure resulting from the usage scenario with a large amount of mothballs placed directly in the living space coincided with reports from the user of a noticeable odor and adverse health effects that the user attributed to mothball use.

4.1.4. Risk perception

There were a wide range of beliefs about the function and hazards[ao][ap] of [aq][ar][as][at][au][av][aw]mothballs among participants, as well as a gap in knowledge between consumer and expert ideas of how the product works. Only 14% of the participants were able to correctly identify an active ingredient in mothballs, while 76% stated that they did not know the ingredients. Similarly, 68% could not correctly describe how moth products work, with 54% of all participants believing that moths are repelled by the unpleasant odor. Two-thirds of participants expressed health concerns related to using moth products[ax][ay]. 43% mentioned inhalation, 38% mentioned poisoning by ingestion, 21% mentioned cancer, and 19% mentioned dermal exposure. A few participants held beliefs that were completely divergent from expert models, for example a belief that mothballs ‘‘cause parasites’’ or ‘‘recrystallize in your lungs.’’

A particular concern arises from the common belief that moths are repelled by the smell of mothballs. This may well mean that users would want to be able to smell the product to know it is working – when in fact this would be an indication that users themselves were being exposed and possibly using the product incorrectly. Improvements to mothball warnings might seek to address this misconception of how mothballs work, and emphasize the importance of closed containers, concentrating the product near the treated materials and away from people.

4.2. Mercury as a consumer product

Elemental mercury is used in numerous consumer products, where it is typically encapsulated, causing injury only when a product breaks. Examples include thermometers, thermostats, and items containing mercury switches such as irons or sneakers with flashing lights. The primary hazard arises from the fact that mercury volatilizes at room temperature. Because of its tendency to adsorb onto room surfaces, it has long residence times in buildings compared with volatile organic compounds. Inhaled mercury vapor is readily taken up by the body; in the short term it can cause acute effects on the lungs, ranging from cough and chest pain to pulmonary edema and pneumonitis in severe cases. Long-term exposure can cause neurological symptoms including tremors, polyneuropathy, and deterioration of cognitive function (ATSDR, 1999).

The second case study focuses on specific uses of elemental mercury as a consumer product among members of Latino and Caribbean communities in the United States. Mercury is sold as a consumer product in botánicas (herbal pharmacies and spiritual supply stores), for a range of uses that are characterized variously as folkloric, spiritual or religious in nature.

4.2.1. Methods

Newby et al. (2006) conducted participant observation and interviews with 22 practitioners and shop owners[az], seeking to characterize both practices that involved mercury use and perceptions of resulting risks. These practices were compared and contrasted with uses reported in the literature as generally attributable to Latino and Caribbean religious and cultural traditions in order to distinguish between uses that are part of the Santeria religion, and other uses that are part of other religious practice or secular in nature. Special attention was paid to the context of Santeria, especially insider–outsider dynamics created by its secrecy, grounded in its histories of suppression by dominant cultures. Because the label Latino is applied to a broad diversity of ethnicities, races, and nationalities, the authors sought to attend to these differences as they apply to beliefs and practices related to mercury.

Uses reported in the literature and reported by participants to Newby et al. (2006) and Riley et al. (2001a, 2001b) were modeled to estimate resulting exposures. The fate and transport of mercury in indoor air is difficult to characterize because of its tendency to adsorb onto surfaces and the importance of droplet-size distributions on overall volatilization rates (Riley et al., 2006b). Nevertheless, simple mass transfer and indoor air quality models can be employed to illustrate the relative importance of different behaviors in determining exposure levels.

4.2.2. Uses

Many uses are enclosed, such as placing mercury in an amulet, gourd, walnut, or cement figure (Johnson, 1999; Riley et al., 2001a, 2001b, 2006b; Zayas and Ozuah, 1996). Other uses are more likely to elevate levels of mercury in indoor air to hazardous levels, including sprinkling of mercury indoors or in cars for good luck or protection, or adding mercury to cleaning compounds or cosmetic products (Johnson, 1999; Zayas and Ozuah, 1996).

Some uses, particularly those attributable to Santeria, are occupational in nature. Santeros and babalaos (priests and high priests) described being paid to prepare certain items that use mercury (Newby et al., 2006). Similarly, botanica personnel described selling mercury as well as creating certain preparations with it (Newby et al., 2006; Riley et al., 2001a, 2001b). One case report described exposure from a santero spilling mercury (Forman et al., 2000). Some of this work occurs in the home, making it both occupational and residential.

Across the U.S. population, including in Latino and Caribbean populations, it is more common for individuals to be exposed to elemental mercury vapor through accidental exposures such as thermometer, thermostat and other product breakage or spills from mercury found in schools and abandoned waste sites (Zeitz et al., 2002). The cultural and religious uses described above reflect key differences in use (including intentional vs. accidental exposure) that require attention in design of risk communications.

4.2.3. Exposures

Riley et al. (2001a, 2001b) solved a single-chamber indoor-air quality model analytically to estimate exposures based on scenarios derived from two interviews with mercury users. Riley et al. (2001a, 2001b) similarly modeled scenarios for sprinkling activities reported elsewhere in the literature. Riley et al. (2001a, 2001b) additionally employed mass transfer modeling combined with indoor air quality modeling to estimate resulting exposures from the contained uses described in interviews with practitioners (Newby et al., 2006).

Results presented in Table 3 show wide variation in predicted exposures resulting from different behavior patterns in different settings. Contained uses produce the lowest exposures. As long as the mercury remains encapsulated or submerged in other media, it poses little risk. By contrast, uses in open air can result in exposures orders of magnitude greater, depending on amounts and how the mercury is distributed, as droplet size and surface area are key determinants of exposure.

4.2.4. Risk perception

Newby et al. (2006) found that participants identified the risks of mercury use as primarily legal in nature.[ba][bb][bc][bd][be][bf] Concerns about getting caught by either police or health officials were strong[bg][bh][bi]. After these concerns, practitioners mentioned the risks of mercury use ‘‘backfiring’’ on a spiritual level, particularly if too much is used.[bj][bk][bl] There was some awareness of potential harmful health effects from mercury use[bm][bn], but the perceptions of mercury’s spiritual power and the perceived legal risks of possession and sale figured more prominently in users’ rationales for taking care in using it and clearly affected risk-mitigation strategies described (e.g., not discussing use or sales openly, giving people a bargain so they won’t tell authorities).

Newby et al. (2006) discuss at length the insider–outsider dynamics in the study, and their influence on the strength of fears of illegality of mercury. Because of taboos on sharing details of Santeria practice, the authors warn against providing certain details of practice in risk communications designed by outsiders, as it would undercut the credibility of the warning messages.

Mental models of risk perception are critically important in all cases of consumer mercury use, both intentional and unintentional. When a thermostat or thermometer breaks in a home, many users will use a vacuum to clean up the spil[bo][bp][bq][br]l, based on a mental model of mercury’s hazards that does not include a notion of mercury as volatile. A key gap in people’s knowledge of mercury relates to its volatility; most lay people do not realize that vacuuming mercury will greatly increase its indoor air concentration, causing a greater health hazard than simply leaving mercury on the floor (Schwartz et al., 1992; Zelman et al., 1991). Thus, many existing risk communications about mercury focus on accidental spills and how (or how not) to clean them up.[bs][bt]

[a]Interesting timing for me on this paper- we’re currently working on a scheme to communicate hazards to staff & faculty at a new facility. We have an ethnic diversity to consider and a number of the spaces will host the general public for special events. Lots of perspectives to account for…

[b]If you have info on this next week, it would be interesting to hear what challenges you have run into and what you have done to address them.

[c]I’d be game for that. I’m just getting into the project and was starting to consider different risk perceptions among different audiences. This paper has given me some food for thought

[d]This is different from the way I have used the term “risk communication” traditionally. Traditionally risk communication is designed to help a variety of stakeholders work through scientific information to come to a shared decision about risk. See https://www.epa.gov/risk-communication for example. However, this paper’s approach soundsm more like the public health approach used to collect more accurate information about a risk

[e]I really like the concept of “behaviorally realistic exposure assessment”. Interestingly, EPA has taken over regulation of workplace chemicals from OSHA because OSHA was legally constrained from using realistic exposure assessment (specifically, the assumption that PPE may not be work correctly all the time)

[f]Wow – that is crazy to hear that OSHA would be limited in that way. One would thing actual use would be an incredibly important thing to consider.

[g]OSHA is expected to assume that all of its regulations will be followed as part of its risk assessment. EPA doesn’t believe that. This impacted EPA’s TSCA risk assessment of Methylene Chloride

[h]There is a press story about this at

[i]I’m wondering if the researchers are in academia or from the company. If from companies which supplied mothballs, I’m surprised that this was not one of the first things that they considered.

[j]That’s an interesting question. Mothballs are a product with a long history and they were well dispersed in the economy before regulatory concerns about them arose. So the vendors probably had an established product line before the regulations arose.

[k]Wondering about the age distribution of the study group- when I think of mothballs, I think of my grandparents who would be about 100 years old now. Maybe younger people would handle the mothballs differently since they are likely to be unfamiliar with them.

[l]I’m also wondering about how they recruited these volunteers because that could introduce bias, for example only people who already know what they are might be interested

[m]Volunteer recruitment is an interesting thought…what avenue did they use to recruit persons who had this product? Currently wondering who still uses them since I don’t know anyone personally who talks about it…

[n]It sounds like they went into the shopping area outside Smith College and recruited people off the street. Northampton is a diverse social environment, but I suspect mothball users are from a particular segment of society

[o]How the recruitment happened seems like a key method that wasn’t discussed sufficiently here. After re-reading this it might be people that they recruited people without knowing if they had used mothballs or not.

[p]Interesting thought. When I was in my undergraduate studies, one of my professors characterized a substance as “smelling like mothballs,” and me and all of my peers were like “What? What do mothballs smell like…?” Curious as to whether product risk assessment is different between these generational groups.

[q]Did you and your undergraduate peers go grab a box and sniff them to grok the reference?

[r]I certainly did not! But I wonder how many people would have, if there were available at the time!

[s]Would anyone like to share equivalents they have seen in research labs? Researchers using a product in a way different from intended? Did it cause any safety issues? Were the researchers surprised to find that they were not using as intended? Were the researchers wrong in their interpretations and safety assessment? If so, how?

[t]I presume you’re thinking of something with a specific vendor-defined use as opposed to a reagent situation where, for example, a change in the acid use to nitric led to unforeseen consequences.

[u]I agree that this can apply to the use of chemicals in research labs. Human error is why we want to build in multiple controls. In terms of examples, using certain gloves of PPE for improper uses is the first thing that comes to mind.

[v]I have seen hardware store products repurposed in lab settings with unfortunate results, but I can’t recall specific of these events off the top of my head. (One was an hubcap cleaning solution with HF in it used in the History Dept to restore granite architectural features.)

[w]I have seen antifreeze brought in for Chemistry labs and rock salt brought in for freezing point depression labs…not dangerous, but not what they were intended for.

[x]So is the take-away on this point and the ones that follow in the paragraph that another communication method is needed? Reading the manual before use is rare (in my experience)- too wordy. Maybe pictographs or some sort of icon-based method of communications.

[y]This seems like to takeaway to me! Pictures, videos—anything that makes the barrier to content engagement as low as possible. Even making sure that it is more difficult to miss the information when trying to use the product would likely help (ie, not having to look it up in a manual, not having to read long paragraphs, not having to keep another piece of paper around)

[z]In the complete article, they discuss three hurdles to risk understanding:

1. Cognitive heuristics

2. Information overload

3. Believability and self-efficacy

These all sound familiar from the research setting when discussing risks

[aa]Curious how many people actually read package labeling, and of those people how many take the labeling as best-practice and how many take it as suggested use. I’m also curious how an analogy to this behavior might be made in research settings. It seems to me that there would likely be a parallel.

[ab]I believe that the Consumer Product Safety Commission does research into this question

[ac]Other considerations: is the package labeling comprehensible for people (appropriate language)? If stuff is written really small, how many people actually take the time to read it? Would these sorts of instructions benefit more from pictures rather than words?

[ad]I was watching an satirical Better Call Saul “legal ethics” video yesterday where the instructor said “it doesn’t matter how small the writing is, you just have to have it there”. See https://www.dailymotion.com/video/x7s7223 for that specific “lesson”

[ae]I think we’d see a parallel in cleaning practices, especially if it’s a product that gets diluted different amounts for different tasks. Our undergraduate students for example think all soap is the same and use straight microwash if they see it out instead of diluting.

[af]Notably, even when putting them outside in a wide area, you can still smell them from a distance, which would make them a higher exposure than expected. Pictures and larger writing on the boxes would definitely help, but general awareness may need to be shared another way.

[ag]Historical use was in drawers with sweaters, linens, etc (which is shown to be the “low exposure”)…were these products inadvertently found to be useful in other residential uses much later?

[ah]I wonder if the “other uses” were things consumers figured out and shared with their networks – but those uses would actually increase exposure.

[ai]It appears so! Another issue may be the amount of the product used. Using them outside rather than in a drawer, may minimize the exposure some, but that would be relative to exactly how much of the product was used…

[aj]The comment about being able to smell it to “know it is working” is also interesting. It makes me think of how certain smells (lemon scent) are associated with “cleanliness” even if it has nothing to do with the cleanliness.

[ak]I’ve also heard people refer to the smell of bleach as the smell of clean – although if you can smell it, it means you are being exposed to it!

[al]This is making me second guess every cleaning product I use!

[am]It also makes me wonder if added scent has been used to discourage people from overusing a product.

[an]I think that is why some people tout vinegar as the only cleaner you will ever need!

[ao]What do you think would lead to this wide range?

[ap]If they are considering beliefs that were passed down through parents and grandparents this would also correlate with consumers not giving attention to the packaging because they grew up with a certain set of beliefs and knowledge and they have never thought to question it.

[aq]Is it strange to hear this given that the use and directions are explained right on the packaging?

[ar]I don’t think it is that strange. I think a lot of people don’t bother to read instructions or labels closely, especially for a product that they feel they are already familiar with (grow up with it being used)

[as]Ah, per my earlier comment regarding whether or not people read the packaging—I am not actually very surprised by this. I think there is somewhat of an implicit sense that products made easily available are fairly safe for use. That, coupled with a human tendency to acclimate to unknown situations after no obvious negative consequences plus the shear volume of text meant to protect corporations (re: Terms of Use, etc), I think people sort of ignore these things in their day-to-day.

[at]I agree it seems that people use products they saw used throughout their childhood…believed them to be effective and hence don’t read the packaging. (Clearly going home to read the packaging myself…as I used them recently to repel skunks from my yard).

[au]Since the effects of exposure to mothball active ingredients are not acute in all but the most extreme cases (like ingestion), it is unlikely that any ill health effects would even be linked to mothballs

[av]I have wondered if a similar pattern happens with researchers at early stages. If the researcher is interested to a reagent or a process by someone who doesn’t emphasize safety considerations, that early researcher things of it as relatively safe – then doesn’t do the risk assessment on their own.

[aw]Yes, exactly. Long-term consequences are much harder for us to grapple with than acute consequences, which may lead to overconfidence and overexposure

[ax]I wonder why with so many having health concerns, only 12% used on the correct “as needed” basis.

[ay]A very, very interesting question. I wonder if it has something to do with a sense that “we just don’t know” along with a need to find a solution to an acute problem. i.e., maybe people are worried about whether or not it is safe in a broad, undefined, and somewhat intractable manner, but are also looking to a quick solution to a problem they are currently facing, and perhaps ignore a pestering doubt

[az]Again here, I’m wondering why more is not described about how they identified participants, because it is a small sample size and there is a possibility for bias

[ba]This is an important finding. Public risk perception and professional risk perception can be quite different. I don’t think regulators consider how they might contribute to this gap because each chemical is regulated in isolation from other risks and exposures.

[bb]It is also related to the idea of how researchers view EHS inspections. Do they see them as opportunities for how they can make their research work safer? Or do they merely see them as annoying exercises that might get them “in trouble” somehow?

[bc]I think that in both Hg case and the research case, there is a power struggle expressed as a culture clash issue. Both the users of Hg for spiritual purposes and researchers are likely to feel misunderstood by mainstream society represented by the external oversight process

[bd]I think this is *such* an important takeaway. The sense as to whether long documents (terms of use and other contracts, etc) and regulatory bodies (EHS etc) are meant to protect the *people/consumers* or whether they are meant to protect the *corporation* I think is a big deal in our society. Contracts, usage information, etc abound, but it’s often viewed (and used) as a means to protect from liability, not as a means to protect from harm. I think people pick up on that.

[be]I am in total agreement – recently I sat through a legal deposition for occupational exposure related mesothelioma, it was unsettling how each representative from each company pushed the blame off in every other possible direction, including the defendant. There are way more legal protections in place for companies than I could have ever imagined.

[bf]There is some discussion of trying to address this problem with software user’s agreements, but I haven’t heard of this concern on the chemical use front.

[bg]This is to say there is a disconnect to reasoning behind the legal implications? Assuming most are not aware of the purpose of the regulations as protections for people?

[bh]I don’t know of any agency that would recognize use of Hg as a spiritual practice. Some Native Americans have found their spiritual practices outlawed because their use of a material is different scenario from the risk scenario that the regulators base their rules on

[bi]I agree with your comment about a disconnect. Perhaps if they understood more about the reasons for the laws they would be more worried about their health rather than getting in trouble.

[bj]To a practitioner, is a spiritual “backfire” completely different from a health effect, or just a different explanation of the same outcome?

[bk]Good question

[bl]Good point – I thought about this too. I’d love to hear more about what the “spiritual backfire” actually looked like. Makes me think of the movie “The Exorcism of Emily Rose” where they showed her story from the perspective of someone who thinks she is possessed by demons versus someone who thinks she is mentally ill.

[bm]I am curious to find out how risk communication plays a role here cause it seems those using the mercury know about its potential health hazard.

[bn]Agree – It does say “some” awareness so I would be interested to see how bad they think it is for health vs reality. It looks like they are doing a risk analysis of sorts and are thinking the benefits outweigh the risks.

[bo]I’m not sure how to articulate it, but this is very different than the spiritual use of mercury. Spiritual users can understand the danger of mercury exposure but feel the results will be worth it. The person wielding a vacuum does not understand how Hg’s hazard is increased through volatilization. I suspect a label on vacuum cleaners that said ‘NOT FOR MERCURY CLEANUP’ would be fairly effective.

[bp]Would vacuum companies see this as worth doing today? I don’t think I really encountered mercury until I was working in labs – it is much less prevalent today than it used to be (especially in homes), so I wonder if they would not see it as worth it by the numbers.

[bq]Once you list one warning like this, vacuum companies might need to list out all sorts of other hazards that the vacuum is not appropriate for cleanup

[br]Also, Mercury is being phased out in homes but you still see it around sometimes in thermometers especially. Keep in mind this paper is from 2014.

[bs]I don’t understand this statement in the context of the paragraph. Which risk communication messages is she referring to? I know that institutional response to Hg spills has changed a lot over the last 30 years. There are hazmat emergency responses to them in schools and hospitals monthly

[bt]I think this vacuum example is just showing how there is a gap in the risk communications to the public (not practitioners), since they mainly focused on clean up rather than misuse. It would be nice if there was a reference or supporting info here. They may have looked at packaging from different mercury suppliers.