The Editor’s Spotlight for the March / April 2017 issue of the Journal of Chemical Health and Safety is shining on:

An exposure assessment of desktop 3D printing by Tracy L. Zontek, Burton R. Ogle, John T. Jankovic, and Scott M. Hollenbeck

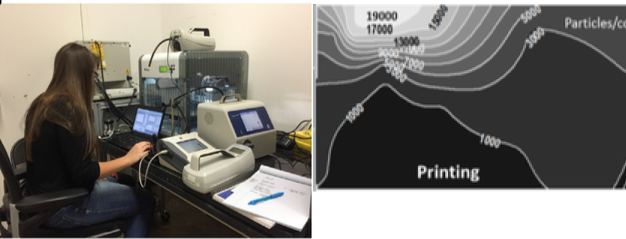

A preliminary hazard analysis of 3D printing included process monitoring in two working environments; a small well ventilated materials development laboratory with a Makerbot printer (polylactic acid filament) and a poorly ventilated lab, home-like in terms of room size and ventilation with a Da Vinci XYZ printer (acrylonitrile- butadiene-styrene).

Particle number, size and mass concentration were measured within the printer enclosures, breathing zone, and room simultaneously. Number concentrations were elevated above background typically in the 103 – 105 particles/cm3 range. During printing >99% of the aerosol number concentration was within the ultrafine particulate (UFP) and nanoscale size range. Condensed aerosol emissions from the Da Vinci XYZ printer was examined by Fourier infra-red spectroscopy and suggested isocyanic acid and n-decane as two possible chemical components. Light microscopy and transmission electron microscopy with energy dispersive analysis by X-ray identified individual and aggregated particles highly suggestive of combustion, accompanied by a variety of metallic elements.

Adverse health effects associated with 3D printing related to chemical vapor off-gassing in well ventilated space appears to be low. At this point the significance of ultrafine particle emission is under growing suspicion in its relationship to inflammatory, pulmonary, and cardiovascular effects. Preliminary recommendations for particulate control developed from this analysis are based on good industrial hygiene practice rather than compelling adverse health effects.

You can download the complete article here. An exposure assessment of desktop 3D printing

Hi everybody 🙂 I’m rather new to 3d printing and I have many questions on the matter, so I hope you won’t get mad at me for asking here at least couple of them. I think even before I’ll get seriously into modelling I should focus on the software I’m going to use, and that’s what I would like to ask you about. Mainly, should I begin with the most simple CAD I can find or would it be better to start on something more complicated? I’m worried that I’ll get some undesirable quirks while working on simpler software. My second question is about the program as well: should I search for software that will let me design and slice it in it, or should I use a separate software for each of them? Does it even make a difference? Surprisingly, I couldn’t find the answer to that, as it seems like most websites want to focus on the very basics (like what is 3d printing and so on), and while the answers to those questions are fine, it seems like no one wants to go into the details (it looks like some of them even plagiarise each other! I swear I’ve read the same answers to the same questions on at least 3 different websites) but I’m getting off-topic… The last question is about 3d pens. Would it be possible to somehow convert whatever I draw with a 3d pen to a 3d model in a software? For example, if I’ll draw a horse with 3d pen, would it be possible to get its outline in a program? I’m not sure how that would even work, but the very idea sounds interesting to me. Anyway, I think I’ll stop here just in case no one will ever answer me and all of this writing will be for nothing. I apologise that I’m using your content to ask questions, but I hope you’ll understand and assist a rookie like me. Anyway, thank you for posting. I did learn something from this and that’s always appreciated. Thank you, and I hope to hear back from you very soon 🙂

This question is outside the scope of our expertise in the Division of Chemical Health and Safety. I suspect that inquiries to the correct forums will produce something useful on this topic, though. Perhaps a search on “3d modeling software discussion” will be helpful?

Good luck.

– Ralph