PubChem LCSS Update – March 2017

The PubChem database, hosted by the US National Library of Medicine, includes a wide variety of data on over 90 million chemical compounds. PubChem’s goal is to make this data accessible to chemists, chemical safety professionals, chemical educators and others working with laboratory chemicals. Data are reported from multiple sources, allowing users to compare and determine the best use of this data in their work. The data are also organized to facilitate downloading in a variety of formats as well via programmatic access for reuse in local software applications.

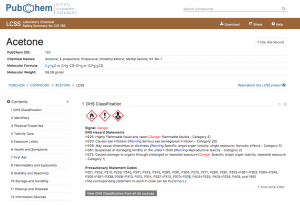

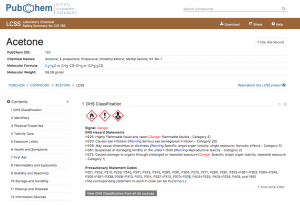

In addition to structural, physical and toxicological raw data, the PubChem collection includes chemical safety information from national and international agencies. For human browsers, this chemical safety information in PubChem is organized into a data view based on the Laboratory Chemical Safety Summary (LCSS) format described in “Prudent Practices in the Laboratory“. This LCSS view chemical and physical properties and safety information for compounds that have Globally Harmonized System designations publicly available. The number of records with this chemical safety information has increased from 3000 in 2015 to more than 103,000 today. LCSS data provided by PubChem are intended to support, but not replace, laboratory risk assessments, Safety Data Sheets and institutional guidance for safe laboratory practices and procedures.

In addition to structural, physical and toxicological raw data, the PubChem collection includes chemical safety information from national and international agencies. For human browsers, this chemical safety information in PubChem is organized into a data view based on the Laboratory Chemical Safety Summary (LCSS) format described in “Prudent Practices in the Laboratory“. This LCSS view chemical and physical properties and safety information for compounds that have Globally Harmonized System designations publicly available. The number of records with this chemical safety information has increased from 3000 in 2015 to more than 103,000 today. LCSS data provided by PubChem are intended to support, but not replace, laboratory risk assessments, Safety Data Sheets and institutional guidance for safe laboratory practices and procedures.

Notably, the data compiled by PubChem includes safety information beyond that generally provided by Safety Data Sheets. This additional information is found in sources such as the NIOSH Pocket Guide, CAMEO and European Chemicals Agency, among others. There are also specific incompatible reactions reported from the Hazardous Substances Data Bank (HSDB), sourced from Sigma Aldrich Safety Center notes, the National Fire Protection Association Fire Protection Guide to Hazardous Materials, Sax’s Dangerous Properties of Industrial Materials, Bretherick’s Handbook of Reactive Chemical Hazards and others.

LCSS data can be viewed online, or downloaded either by individual compound or in bulk. In this way, PubChem information can be used to support electronic safety tools such as institutional chemical inventory management systems or laboratory-specific personal protective equipment guidelines. More information about this feature can be found here.

Traffic to the safety information in PubChem has increased over 80% in the past year. The PubChem staff are interested in continuing to improve the usability and accessibility of this information to the laboratory community. To this end, representatives of the ACS Divisions of Chemical Information (CINF) and Chemical Health and Safety (CHAS) are working with the PubChem staff to identify additional sources and uses for health and safety data. Efforts are also underway to improve annotation of the data and enable more specific data retrieval options. We welcome ideas for organization and presentation of the data. To participate or provide comments, contact the CINF safety representative, Leah McEwen at lrm1@cornell.edu or the CHAS secretary, Ralph Stuart at ralph.stuart@keene.edu.